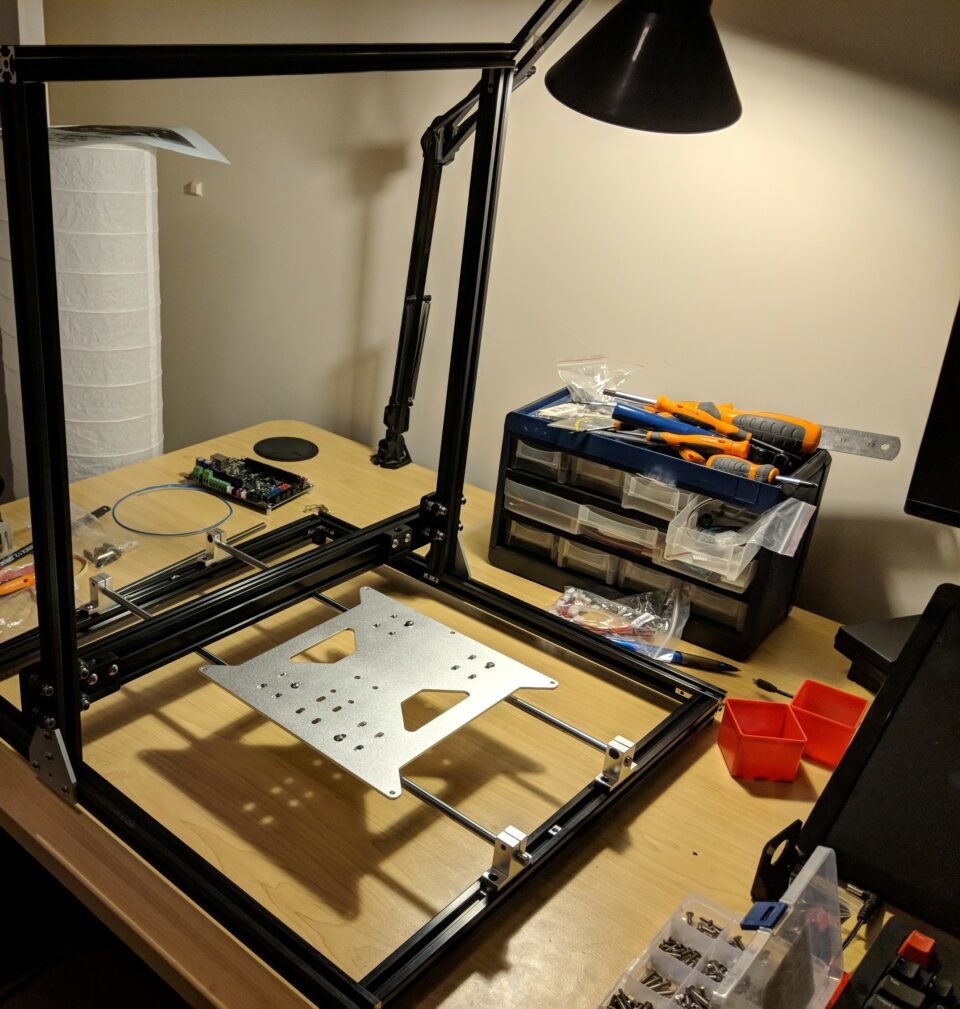

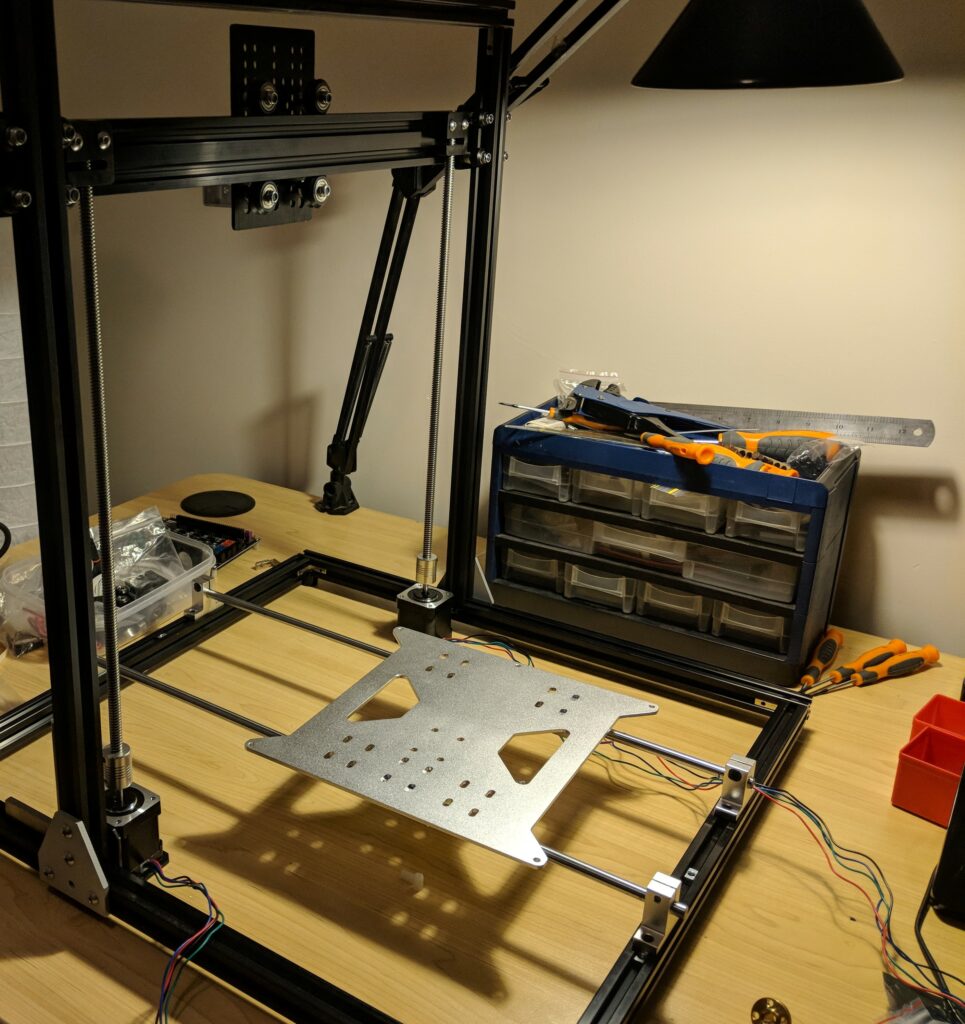

This post lists some 3D printer/CNC machine parts and how they are speced. There is a list of keywords at the end for searches on AliExpress and Ebay.

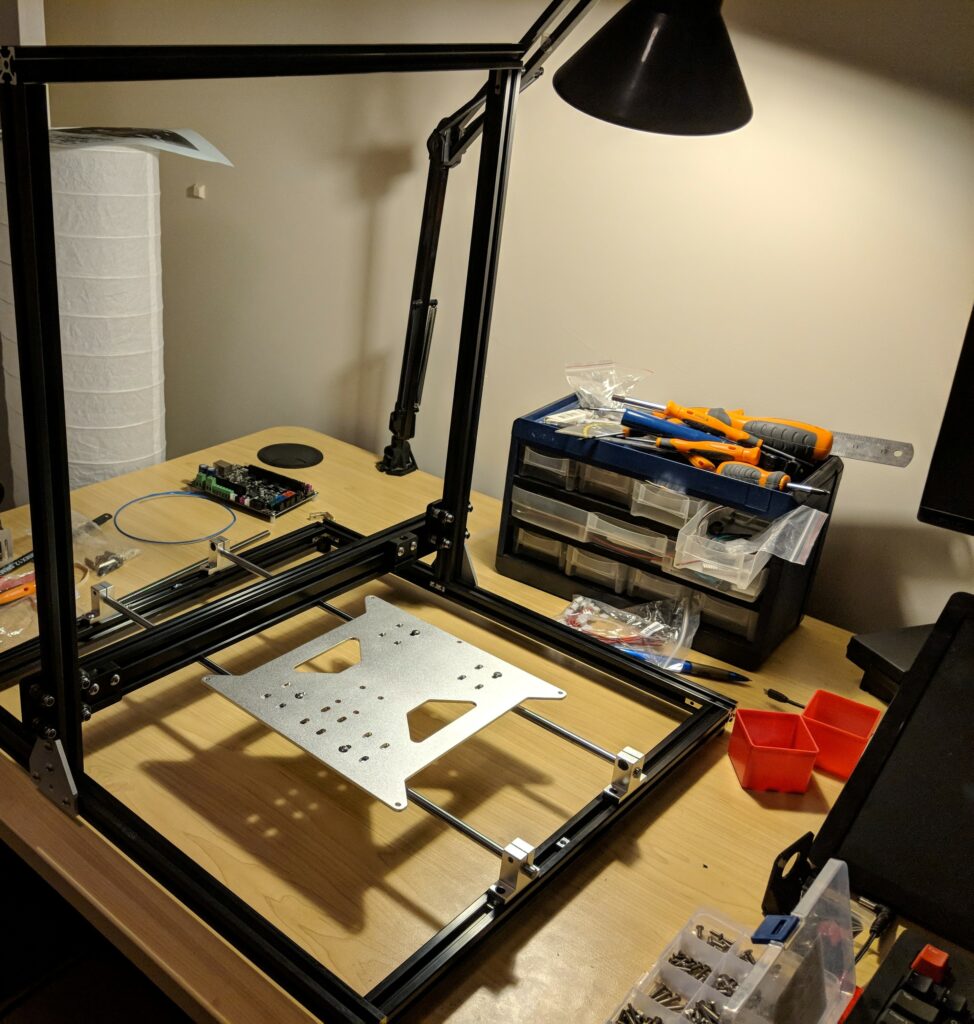

Part selection (and some design notes)

| Part name | Purpose | Dimensioning | Notes |

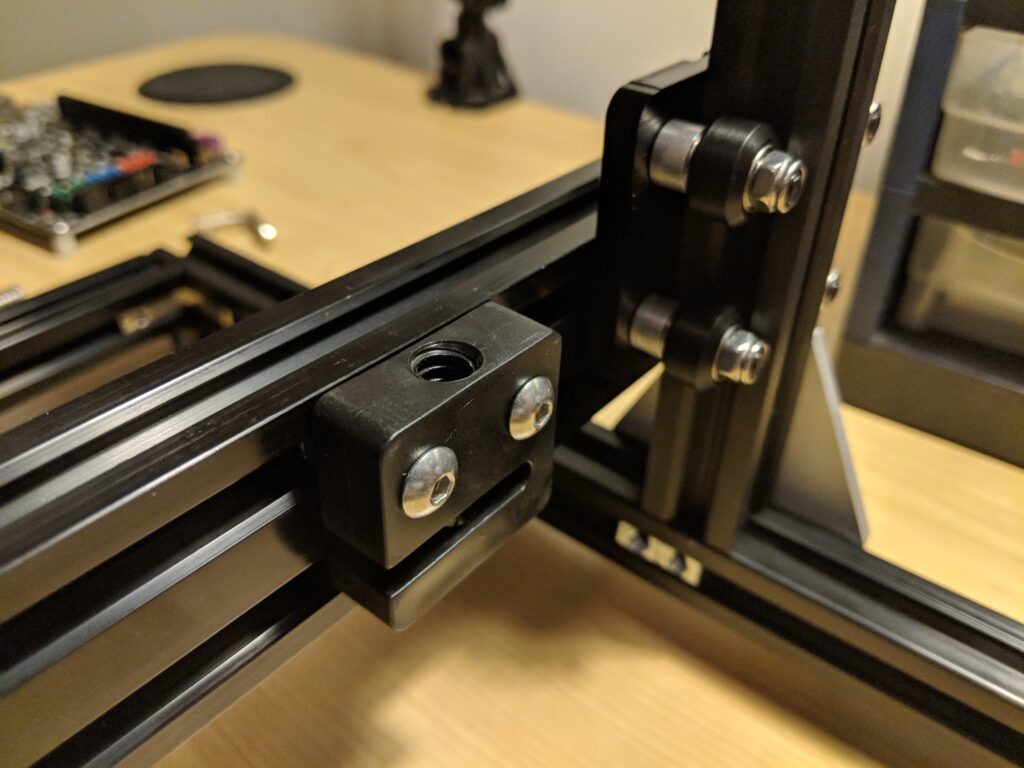

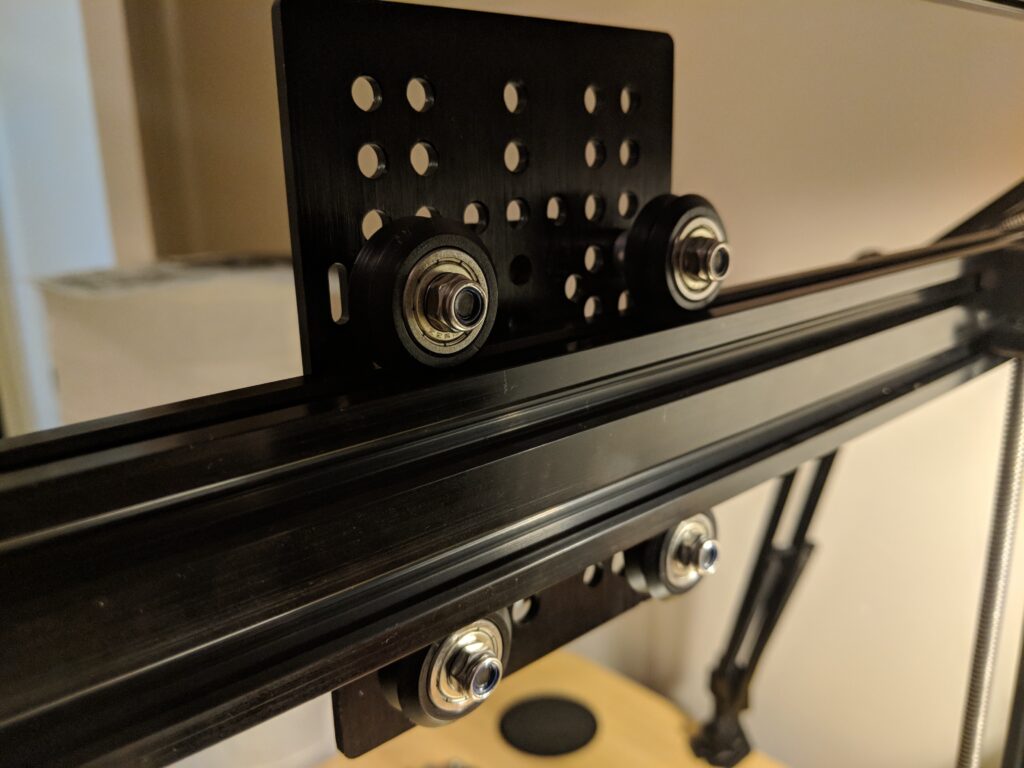

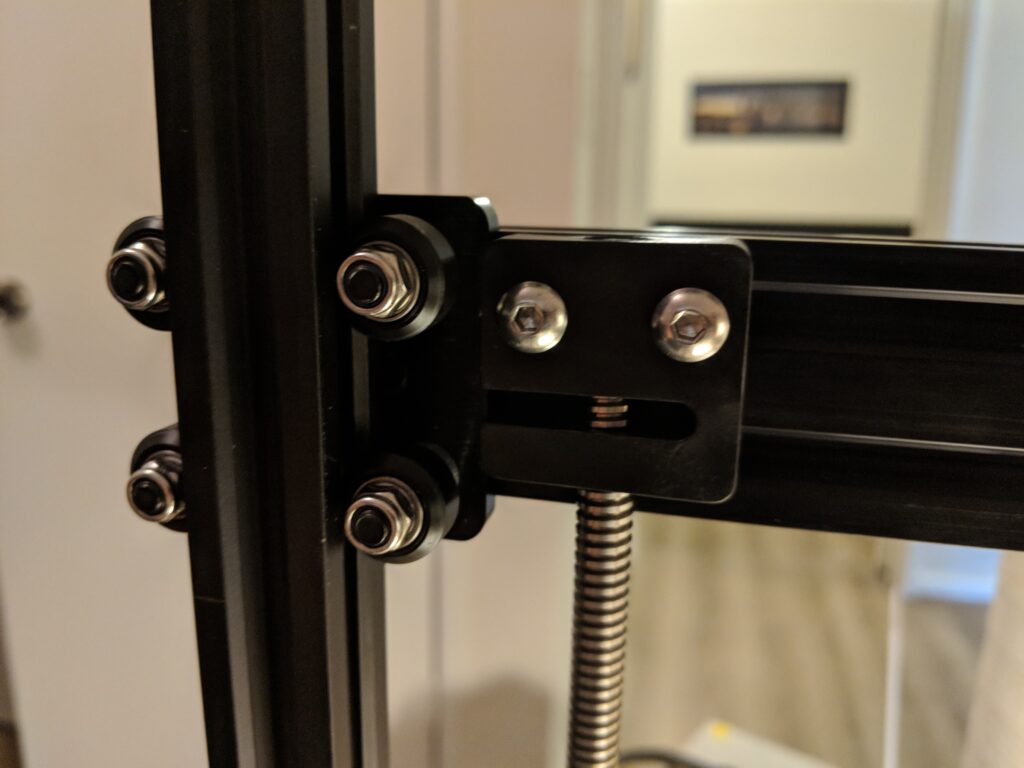

| Aluminium Extrusion Beams | For the frame and axis assembly | 2020 represents 20mm by 20mm at a given length, 2040 means 20mm by 40mm. The system comes in T-slot and V-slot. For frame parts that run gantrys, you must use V-slot type alumium extrusions. | 2020,2040,2060,2080,+ |

| T-Slot corner nuts | Connect frame parts at right angles | ||

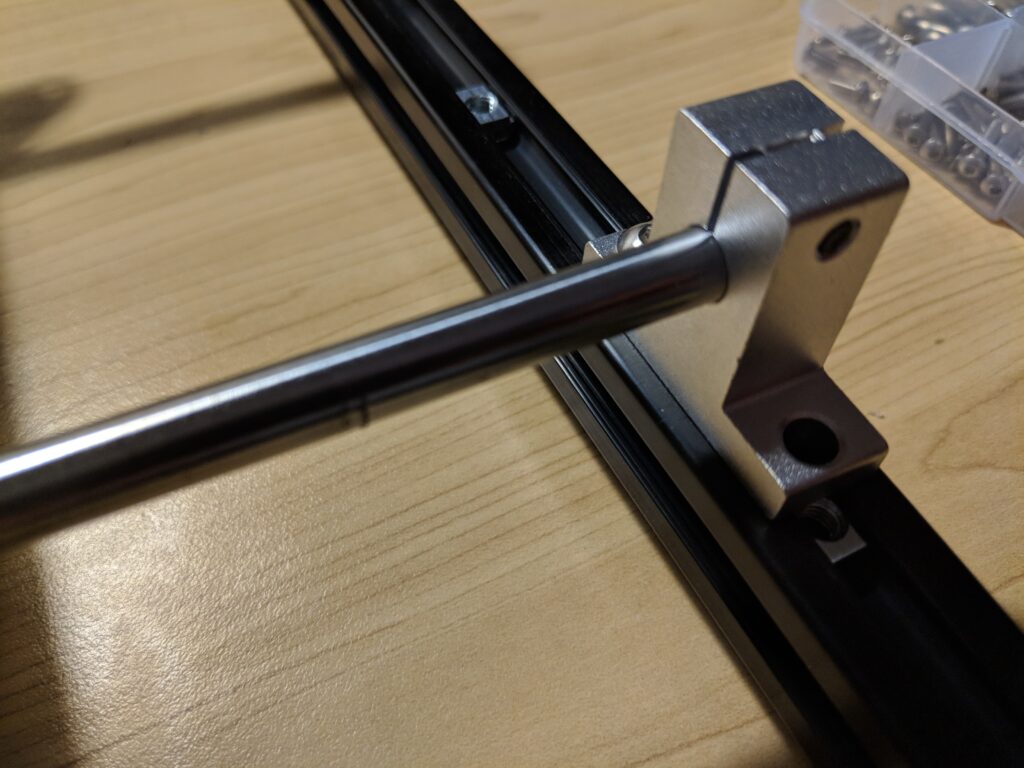

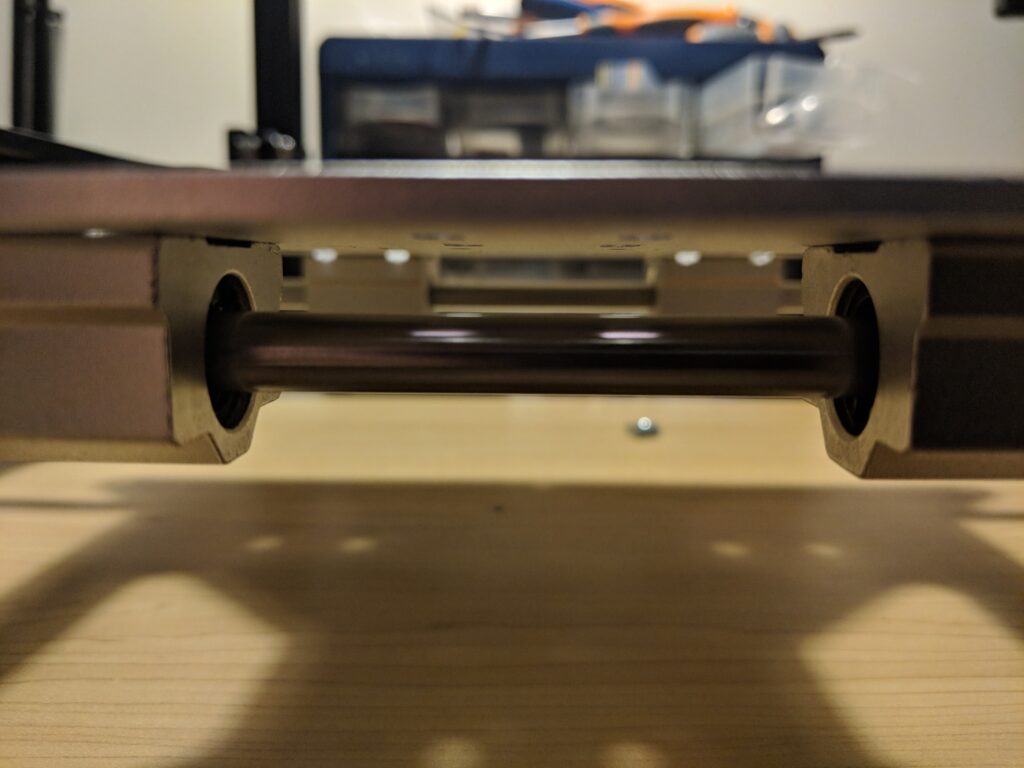

| Threaded Rods | Z-axis (vertical) movement of X-axis assembly | Are sized according to length, diameter (8mm), lead, and pitch. Since I use them for vertical movement, I chose lead and pitch of 2mm. This means one revolution of the rod results in a displacement of 2mm. | Other sizes available include a pitch of 8mm. i.e. one revolution creates 8mm displacement. I chose not to use this because I wasn’t sure the motor could handle it. More displament per revolution means faster movement, but could potentially mean you motor can’t handle it and loss of accuracy. For stepper motors with 200 steps, that would be 8/200 as the minimum distance it can travel. Probably fine anyway, but I didn’t want to risk it. |

| Slot nuts | Metric threaded nuts that allow mounting of components to the slotted frame | various Metric nut sizes compatible with different types of t-slot frames. Used slot nuts for 2020 M5 | |

| Stepper motors | Drive your gantry assembly and create motion on your axis | Used NEMA17 stepper motors which are widely used in 3D printing | Note that they are small cubes of 42mm side length—much smaller than I expected! Pictures and videos make them look like they are approx. 60mm cubes. |

| End stop switches | Small phyical switches to limit axis movement and prevent printer damage | ||

| Timing Belts | Move the X and Y axis | GT2 belts are most commonly used for 3d printing. They are 6mm belts. You should get GT2 pully gears with 16 teeth because that eliminates rounding inaccuracies in distance calculations (as the calculations produce whole numbers). THis is not the case for gears with more teeth. (could not find source reference for this information) THe other type of timing belt will produce artifacts in your print because it causes belt vibration. (the belt teeth are trapezoid shaped). | |

| Controller | The heart of your printer, does all calculations, controls stepper motors, extruder, hotend temperature and heatbed. | ||

| Heater cartridge | Heats your printers hotend to the desired temperature. | 6mm diameter for most hotends | |

| THermistor | Temperature sensor for hotend. Used by controlle board to regulate hotend temperature. | Check which type of THermistors your controller board can read by default. |

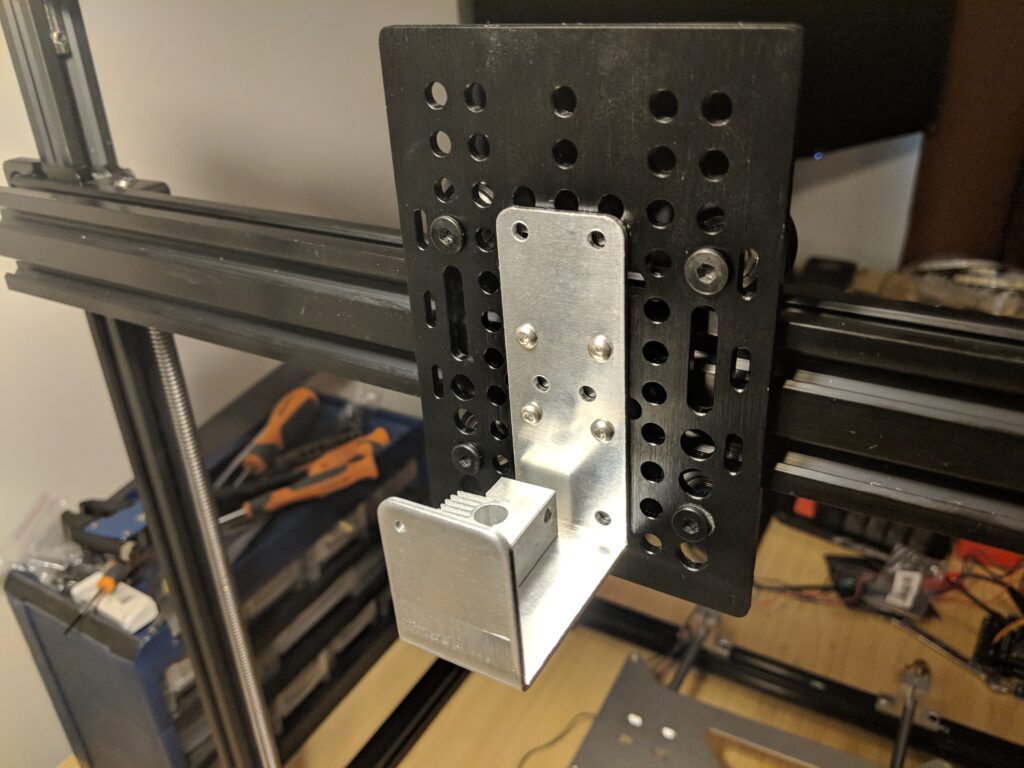

Check out the Openbuilds webstite for inspiration and parts. They have build a whole ecosystem of parts to be used for building CNC machines and gantry/axis systems. Including plates, wheels, rails, frames and other miscellaneous parts. {: .warning}

The full list of search keywords is here. I suggest typing them into AliExpress or Ebay to view pictures of the parts. One difficulty I had was not knowing what certain parts are called (such as gantry plates, timing belt pullys, build plate, bed levelling screws, and v-slot gantry)

- 2040 X Axis Beam

- Frame Z Axis Vertical

- T-Slot Corner Nuts

- T-Slot Nuts

- Linear Rods Base Plate

- Timing Pulleys

- T8 Rod Screw OD

- Motors Nehma 17

- Heatbed

- Base Plate T8 Thread

- T Plate

- End Stop Switches

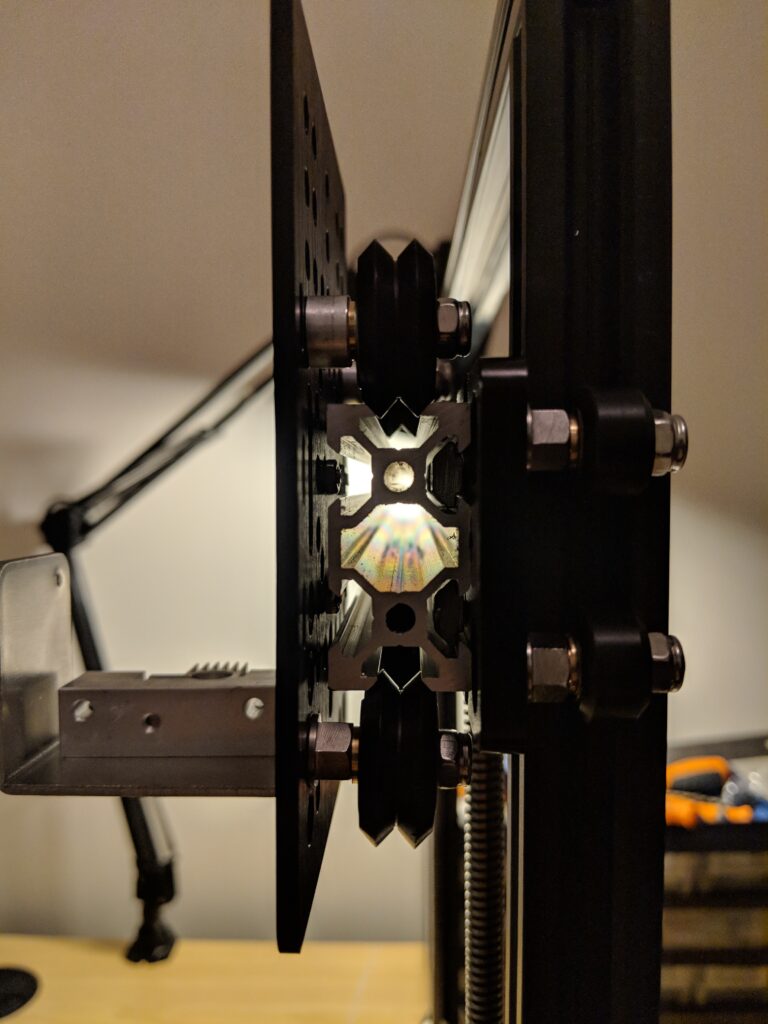

- Axis Gantry Plate Set

- Extruder & Hotend

- Controller

- Timing Belt

- Timing Belt Pullys

- Motor Mounting Bracket

- Motor Mounting Bracket

- Power supply

- Extruder Mounting Bracket

- Build Support Plate

- Build Plate

- Filament

- Bed Levelling Screws

Hindsight is 20/20: Do not attempt to design a 3D printer from scratch without any prior 3D printing knowledge. I underestimated the scope of this endeavour and the complexity of the machines. There are open source 3D printer designs with development teams who have designed, built, tested and improved many iterations of their designs. Most notably, check out the Voron, Hypercube Evolution and DBot open source plans. The Voron even comes with a bill of meterials, Lego like assembly instructions and a CAD model of the assembled printer.